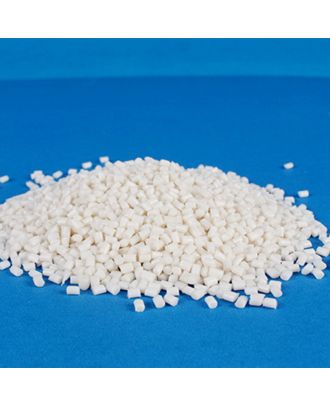

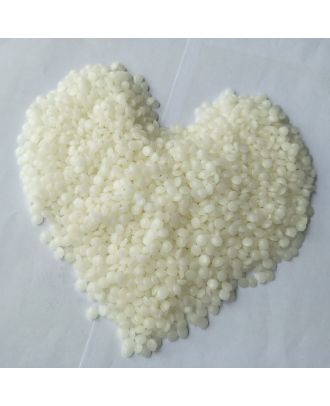

PV3000G Bioplastic PLA Pellets | 25kg

In stock

SKU

ECO-SBPPLPT564

$168.27

Quick Overview

- Material Bioplastic Pellets

- Dimensions Pellets (granular form)

- Certifications ISO 1133, ISO 1269, ISO 11357, ISO 1183, ISO 527, ISO 179, ISO 75

- Shelf Life Indefinite under proper storage conditions

- Size 25kg per bag

- Lining/Coating Aluminum foil bag packaging

- High-performance bioplastic pellets

- Designed for advanced molding and extrusion applications

- Superior tensile strength (30-35 MPa)

- High heat resistance (>130°C)

- Enhanced crystallinity (55-65%) for durability

- Biodegradable and eco-friendly

- Request for Quote More Details

PV3000G is an advanced bioplastic raw material specifically designed for injection molding, extrusion, and thermoforming applications. Its high crystallinity and heat resistance make it an excellent alternative to traditional plastics while maintaining superior mechanical performance. Performance Table

Note: The typical values are provided as a reference for processing but do not guarantee the minimum/maximum quality index or other usages. | ||||||||||||||||||||||||||||||||||||||||||||

Features

Uses

| ||||||||||||||||||||||||||||||||||||||||||||

Environmental Benefits

Awareness

| ||||||||||||||||||||||||||||||||||||||||||||

FAQ Q1: What industries can use PV3000G? A1: It is ideal for food packaging, disposable cutlery, and rigid biodegradable components. Q2: Is PV3000G home-compostable? A2: No, it requires industrial composting conditions. Q3: What makes PV3000G different from other bioplastics? A3: It has superior heat resistance (>130°C) and higher crystallinity (55-65%). Q4: What is the best way to store PV3000G? A4: Keep in a dry, cool storage area to maintain pellet quality. Q5: Can I order a custom formulation? A5: Yes, custom formulations are available for bulk industrial applications. |

Write Your Own Review

We found other products you might like!