Revolutionizing Manufacturing: Injection Molding Grade Bioplastics

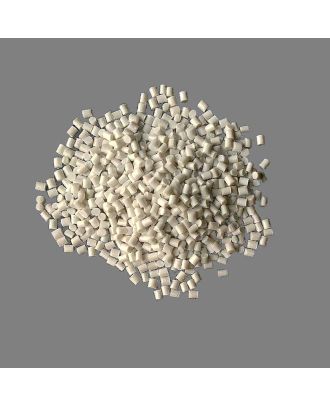

Explore how Injection Molding Grade Bioplastics from Ecopha are setting new standards in the manufacturing industry with their eco-friendly and robust properties.

The world of manufacturing is on the cusp of a significant transformation, spearheaded by the advent of Injection Molding Grade Bioplastics from Ecopha. This comprehensive blog post delves into the heart of this transformation, exploring how these innovative materials are redefining the norms of injection molding, a cornerstone process in the manufacturing industry.

Features Highlight

- High-quality bioplastic material suited for injection molding

- Reduced environmental impact

- Exceptional strength and durability

Overview

- An insightful overview of Injection Molding Grade Bioplastics, discussing their properties, applications, and how they align with sustainable manufacturing goals.

Advantages & Benefits

- Eco-friendly alternative to traditional plastics

- Ideal for a variety of manufacturing applications

- Contributes to sustainable production cycles

Dive into the world of Injection Molding Grade Bioplastics by Ecopha, a pioneering solution in the field of manufacturing. This blog post sheds light on how these bioplastics are transforming the injection molding process, offering a greener and more sustainable alternative to conventional materials. It highlights the benefits and applications of these bioplastics, emphasizing their role in reducing the environmental impact of manufacturing practices.

FAQs

What makes Injection Molding Grade Bioplastics eco-friendly?

These bioplastics are derived from renewable resources, reducing reliance on fossil fuels and minimizing environmental impact.

Can these bioplastics be used for complex product designs?

Yes, they offer excellent moldability, making them suitable for intricate designs and detailed products.

Are Injection Molding Grade Bioplastics as durable as traditional plastics?

Absolutely. They are designed to offer high durability and performance, comparable to conventional plastics.

Do these bioplastics support a circular economy?

Yes, by being more sustainable and potentially recyclable or biodegradable, they align with the principles of a circular economy.